Puredyne Logo

Following the success of preeflow, ViscoTec has expanded its portfolio and launched another brand called “Puredyne”. With the launch of the new bioprinting brand, the innovators are sending a clear message: Precision and repeatability combined with compact design also works in bioprinting!

Extrusion-based bioprinting is a common but not always trouble-free process. The new Puredyne by ViscoTec brand of bioprinting printheads promises a more precise printing process than previously possible – process-safe, repeatable, and so simple that users can fully focus on their research.

Puredyne application example

According to the business development team behind the new brand, Puredyne perfectly fills the gap that has made working in extrusion-based bioprinting difficult to date: “Until now, there have been two options for extrusion-based bioprinting: Either syringe extrusion by extrusion spindle, which is very accurate but requires a great deal of installation space. Or pneumatic extrusion, which offers no options for retraction or control over cleaning. This gap is seamlessly closed by Puredyne’s bioprinting printhead – with highly accurate print results and compact design.“

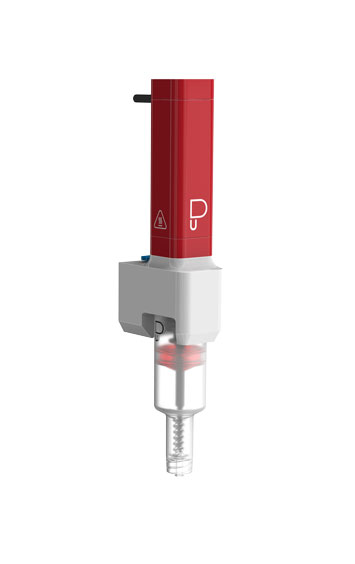

Printhead with single-use cap

Bioprinting printhead with single-use cap: Puredyne® kit b

The compact print head with integrated compressed air supply is mounted as a multi-use component on a 3D printer or bioprinter. A stepper motor ensures simple control; no additional control is necessary. The print head is supplemented by patented single-use caps. The progressive cavity technology is the key to maximum precision. The cap comprises a volume reservoir of 5 ml and is replaced after the dispensing process. The exchange process guarantees absolute safety: There is no cross-contamination as only one material is used per cartridge. The Luer Lock connection at the lower end of the cap allows for the connection of a wide range of different dispensing needles.

Progressive cavity technology in bioprinting

Progressive cavity technology is ideally suited for volumetric dispensing of low to high viscosity biomaterials. Precision, repeatability, process reliability and intuitive handling are the core competencies of ViscoTec technology. Materials of a wide range of viscosities are applied reliably and precisely – for a perfect print result. Due to the reliable technology, environmental influences can be virtually ignored in the printing process. In accordance with the dispensing geometry, a constant volume per revolution is always delivered and precisely applied. The option of reversing the conveying direction ensures clean start and finish points.

For more than 25 years, the dispensing experts at ViscoTec have been working almost exclusively on the precise and gentle dispensing of liquids and pastes. It is precisely this experience that users in the field of bioprinting can now take advantage of. Puredyne facilitates the processing of an almost unlimited range of liquid to pasty materials.

This is Puredyne: Compact design with patented single-use cap and proven progressive cavity technology – for superior process control in bioprinting.

The post ViscoTec Introduces Its New Puredyne® Brand appeared first on ViscoTec Pumpen- u. Dosiertechnik GmbH.