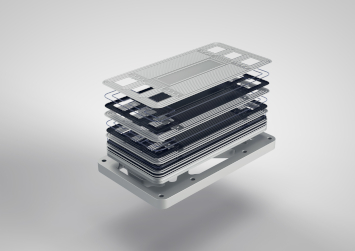

Structure of a fuel cell stack

The current, worldwide demand for environmentally compatible and efficient mobility brings fuel cell technology back to the forefront of strategic discussions.

At the same time, fuel cells and hydrogen promise large potential. Looking at the market and the maturity of the technology, it can be seen, that fuel cell applications still claim a small market share but have already gained a great deal of momentum. In line with this development, dispensing tests were recently carried out at the ViscoTec technical center using a Wacker silicone to seal bipolar plates for fuel cells.

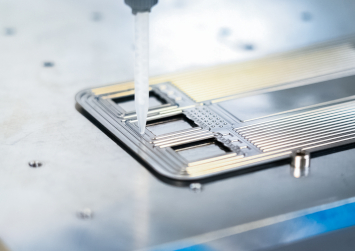

The aim of the dispensing tests: To apply the sealing seam to a bipolar plate in compliance with precise specifications regarding height tolerance. Due to such tests, it is possible to determine process parameters and minimize risks – in order to be able to deduce continuous improvement measures from them. The test was carried out with the 2-component Dispenser P4/4, at a dispensing speed of 0.12 ml/s. The tolerance of the sealant bead was not exceeded. The tolerance of the sealing bead was +/- 0.05 mm – already an impressive result, which the dispensing technology experts want to improve even further.

You can find more information about the dispensing tests in the video on YouTube.

Dispensing test for a sealing bipolar plate for a fuel cell

The system design is adapted to the needs of the customer or to the requirements of the respective application. For example, the dispensing capacity can be adjusted individually. As a system supplier for process-safe, precise, and scalable dispensing technology, ViscoTec is a sought-after partner in a wide range of industries. With the help of special business development units, ViscoTec works together with research institutions, machine builders and end customers on improved and automated production methods. ViscoTec can draw on a wide range of synergies here, but thanks to its own technical center it can also carry out extensive trials and generate process knowledge.

In the fuel cell sector too, the dispensing experts are supporting the development of the market and want to enable customers to achieve continuous growth. Industry experts see a potential of EUR 65 billion in sales in Europe and a further EUR 65 billion in global markets in this future mass market.1 China, Japan, and South Korea in particular, but also the USA, should be considered as sales markets so that the current export strength continues to be maintained for domestic companies. In order to exploit the future growth potential of the hydrogen and fuel cell industry and to remain competitive in the international arena, it will be crucial in the next two to five years to continue to build up and expand existing competencies through investment.

ViscoTec is always ready to provide proactive support and create added value. After all, if dispensing for bonding or sealing components such as bipolar plates is the goal, economic benefits and technical accuracy must be possible even for small quantities. It is therefore crucial to facilitate access with moderate investment costs, but also to ensure scalability by means of a well-thought-out system configuration. Particularly scalability and the associated cost degression must be calculable for customers.

The post Sealing of bipolar plates for fuel cells appeared first on ViscoTec Pumpen- u. Dosiertechnik GmbH.