Automotive loudspeaker casing: 2-component sealant bead application using the ViscoDuo-P 4/4

The progressive development in electromobility sets new standards – also for perfect dosing results. Encouraged by state funding and research programs, for example, numerous institutes and companies worldwide are researching the further technical development of the battery cell. The goal is to be able to achieve higher capacities with faster charging times in smaller and lighter designs.

The increased demand requires, among other things, a conscious handling of the resources to be processed during production. In the application of the material, a flexible and highly accurate dosing is required.

In electro-mobility dosing applications, the focus is on fast and uncomplicated processing of materials, combined with defined cost control. Particularly challenging are applications of materials with high viscosities and abrasive properties. The specific characteristics of the materials must be maintained and not be affected by the dosing process, even in the case of high filler content.

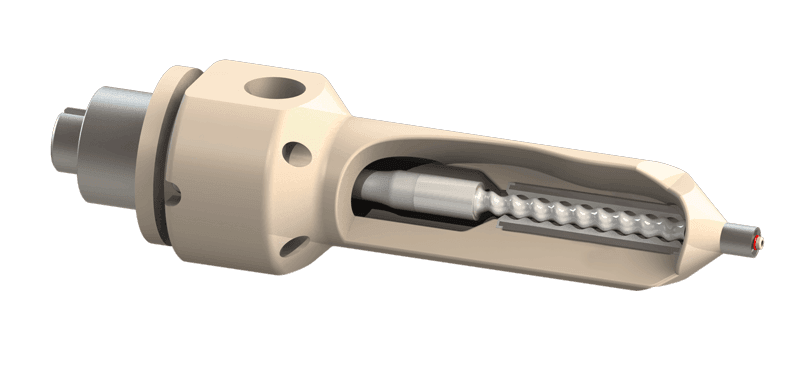

Dispenser (metal-free in the wetted parts area) for special dosing processes, e.g. in battery production

Dosing systems based on the endless piston principle – such as those in the ViscoTec portfolio – offer excellent conditions for the processing of all low to high viscosity 1-component and 2-component materials, such as gap filler and liquid seals or in potting and bonding applications. The combination of rotor and stator with defined volumetric chambers in the dispensers ensures a volumetrically precise, low-shear and virtually pulsation-free application. The endless piston dosing technology is viscosity-independent, valve-less and backflow-free. This guarantees a highly reproducible dosing result.

The elastomers used in the stators of ViscoTec’s dosing pumps undergo a continuous optimization process and have outstanding properties compared to other polymers, including, for example, very good resistance to wear and chemicals. An elastomer recipe has been developed especially for chemically aggressive dosing materials.

ViscoTec dosing systems are particularly impressive when dosing abrasive materials with outstanding results. Sedimentation of the filler of different densities is prevented by the consistent volume flow in the endless piston dispenser.

ViscoTec’s long term goal is to prioritize the cooperation between customer, material manufacturer and dosing technology. The qualification of suitable solutions from the material selection to the implementation of the dosing system in the manufacturing process for the components of an electric vehicle, requires a high degree of know-how and a very close cooperation of all involved. To achieve a tailor-made definition of the dosing equipment, engineering and consulting services are an essential part of the scope of service before, during and after the decision-making process.

Well prepared for the future of e-mobility

Josef Donislreiter, Business Development Manager E-Mobility, ViscoTec Pumpen- u. Dosiertechnik GmbH

To be able to offer the best possible service now and in the future, Business Development Manager for e-mobility, Josef Donislreiter, has been reinforcing the sales team at ViscoTec since November 2017. “In order to be able to react to the ever-growing applications in the field of E-Mobility and to support our customers with focused knowledge, we have expanded our sales team within this area. We are very pleased to have Mr. Donislreiter on board for this task and are convinced that his experience and knowledge will be of great benefit to us in the future.” explains Georg Senftl, Managing Director of ViscoTec.

Accurate cost control due to the reduction of material costs, avoidance of additional production steps, simplification of the dosing application and an increase in the production volume, are always the focus of the dosing technology specialists – without losing the freedom of design in the application. Simulations and validations of dosing applications in the laboratory, including the verification of all parameters, provide tailor-made customer-specific products and systems. And with it, integrated solutions for sustainable development in the field of e-mobility.

Here you can find further information about dosing in e-mobility.

The post Perfect dosing results in the field of e-mobility appeared first on ViscoTec Pumpen- u. Dosiertechnik GmbH.