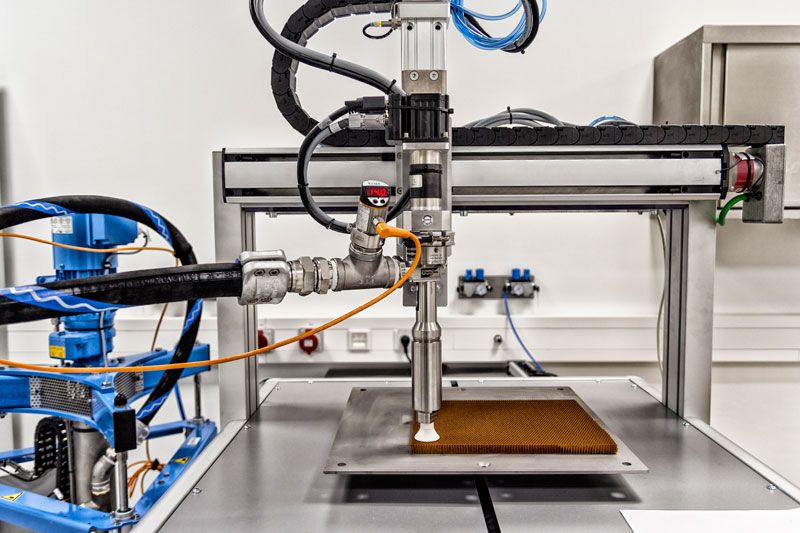

Experimental setup with dosing technology for honeycomb filling in the ViscoTec technical centre – for automated manufacturing

ViscoTec Pumpen- u. Dosiertechnik GmbH and Airborne signed a cooperation agreement at JEC World 2018 in Paris. The dosing technology manufacturer and the supplier of automated and digital manufacturing solutions for composites, decided to enter a partnership. The aim is to develop and supply an integrated and automated solution for the filling of honeycombs with casting compounds. The partnership offers the global composite manufacturing industry an intelligent and fully automated total solution with numerous advantages: The weight of the final product is lower, labour and material consumption are drastically reduced. The partnership also offers customers significant added value: Cost savings through higher accuracy and repeatability of the casting, reduction of material waste and manual work.

Two specialists for automated manufacturing

Nozzle specially developed for the application for filling the honeycombs

The complementarity of the core competencies of ViscoTec and Airborne is demonstrated for the first time in automated honeycomb production. ViscoTec’s strength is the handling and the dosing of highly viscous materials and Airborne’s strength lies in the development and delivery of automated and digital composite manufacturing solutions. „ViscoTec and Airborne are specialists in what they do and know how to handle complex processes and materials,” says Arno van Mourik, CEO of Airborne. “Through this partnership, we are able to offer our customers turnkey automated manufacturing solutions to significantly reduce their manufacturing costs.”

Georg Senftl, ViscoTec’s managing director: “I am sure that this will be a productive partnership for both companies. We want to help our customers to produce better and more competitive products. By partnering with Airborne, we can help our customers automate their production lines.”

About Airborne:

Founded in 1995 and headquartered in The Hague (the Netherlands), Airborne is recognized as a technology leader in advanced composites, focused on the automation and digital manufacturing of composites for the aerospace, automotive, marine, oil & gas and consumer electronics industry. Airborne’s market position is maintained through 150 highly qualified employees working at Airborne’s facilities in the Netherlands, United Kingdom and Spain.

The post Automated manufacturing in the aerospace industry appeared first on ViscoTec Pumpen- u. Dosiertechnik GmbH.