Increased demand for eye and eyebrow cosmetics requires more flexible and faster production processes for manufacturing and filling of materials. Automation (or partial automation) in certain processes, such as emptying or filling, can be the necessary optimization. Progressive cavity pumps offer great potential, especially when processing fluids and pastes.

If one follows the trends in Asia – where masks have long been part of everyday life in public – the demand for make-up products for the upper face area will also increase in Europe and worldwide. Mascara, eyeliner, eye shadow and concealer are particularly sought after because of the current obligation to wear masks. Like in Asian countries, many people will continue to use nose and mouth protection, even after they are no longer legally required.

Higher demands must be covered by production

While retailers must now increasingly distribute make-up instructions and tutorials matching the protective mask, i.e. via social media; manufacturers and bottlers of eye and eyebrow cosmetics are facing completely different challenges. They must cover the higher demands in their production. And at the same time need to make sure that quality and product properties do not suffer as a result.

Automated emptying and filling

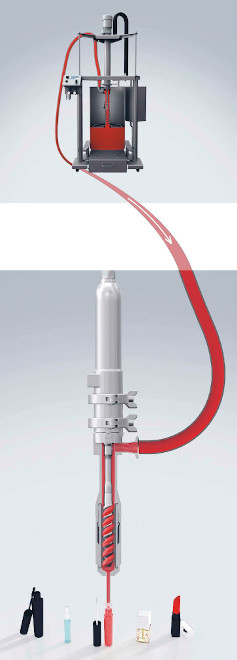

The materials are emptied from the drums and fed directly to the filling machine through a hose.

The material for filling is often provided in drums. This means that in the first step, the often viscous materials, must be emptied from the barrels step. ViscoTec offers a solution especially for materials with high viscosities (up to 7.5 million mPas) with the ViscoMT emptying systems. The materials are emptied from the drums and fed directly to the filling machine through a hose. They are particularly low-shear, virtually pulsation-free and 2-point pressure-controlled.

There are (almost) no limits in the design of the protective masks. They are available in the most diverse forms. And above all, they are also available in a wide range of colors – single-colored or with patterns. The color selection of the cosmetics must also match this, as the wearers will match their make-up to their face mask. For production, this means that it is becoming increasingly important to fill small batches of the most diverse products in a short time. Fast reaction to market requirements can only be achieved with flexible systems. For example, simple mascara must be able to be processed just as well as shear-sensitive mascara with artificial silk or nylon fibers. You can find more about automated mascara production here: https://www.viscotec.de/en/automated-mascara-production/

Filling systems from ViscoTec can be individually configured to meet your requirements in terms of hygienic design, documentation, elastomer compatibility, implementation and dosage or filling volume. Matched to your application. Different products can be filled with one and the same dispenser.

Corona changes our lives. But for all its evil, it also creates potential for industry. Despite lock-down and contact restrictions, there are still numerous opportunities to put on make-up. Be it just for yourself, or for a video chat with colleagues or friends. Create the necessary conditions in your production processes!

The post Protective Masks Requirements as a Driver for Automated Production appeared first on ViscoTec Pumpen- u. Dosiertechnik GmbH.