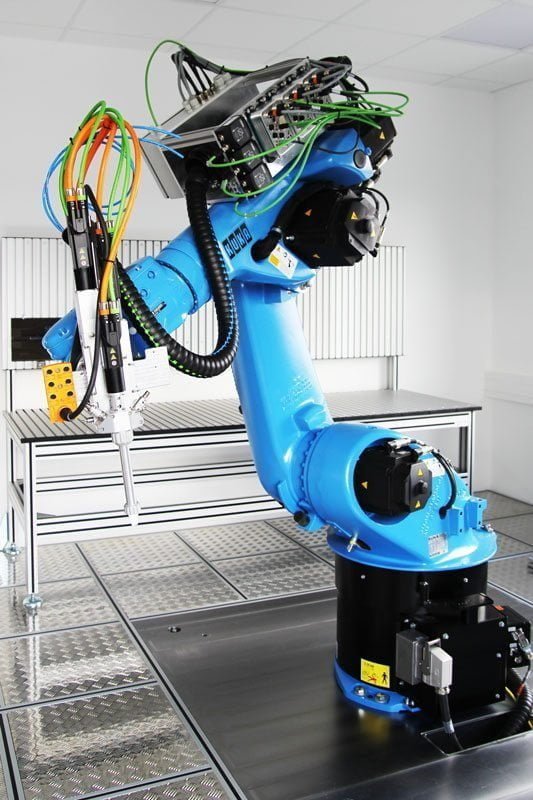

The kuka robot KR 30 is available from now on for dispensing tests at ViscoTec technical centres – here with a vipro-DUOMIX 2-component dispenser from ViscoTec for aerospace applications.

The ViscoTec Customer & Innovation Center (CIC) which opened in September 2017 has now one more highlight. A new KUKA robot for precise customer pretests complements the technical laboratory equipment.

With its ultra-modern technical centres, the CIC offers optimum conditions and sufficient space for numerous customer tests. To further expand and improve the customer service ViscoTec recently decided to purchase a new KUKA robot. The KR 30 has six movable axes and weighs 635 kg. With a position repeat accuracy of ± 0.06 mm, the robot achieves a maximum speed of 2 m/s and can carry up to 30 kg. The maximum reach is 2033 mm.

The robot will primarily be used to test dispensing applications on larger components in which a complex contour is to be coated with a longer dosing bead. Curves or gradients on the component do not pose any problems. In addition, the robot can move both one-component dispensers and two-component mixing heads.

For ViscoTec, the focus is on problem solving of their customer’s applications who transport, dispense or process highly viscous or pasty materials in a fully or semi-automatic environment. In addition to production processes like laser cutting and forging systems, the robot can also be used for adhesive and sealant applications and is therefore perfectly suited for dispensing trials. With various materials in various application areas.

The post New KUKA robot for dispensing tests appeared first on ViscoTec Pumpen- u. Dosiertechnik GmbH.