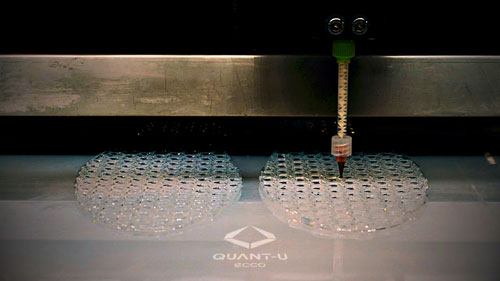

ECCO is a heritage footwear brand and manufacturer from Denmark. QUANT-U is the latest project from the Innovation Lab of ECCO focused on the additive production of midsoles out of a heat cured 2-component silicone, in-stores within 2 hours. The challenge is to produce 3D-printed midsoles in an additive manufacturing process, which are customized for each customer.

The innovation: Shoe soles out of the 3D printer

Personalized shoes have always been the epitome of footwear, however the cost, expertise and time required to manufacture made them exclusive to the elite of society. This is now about to change: ECCO’s idea is to manufacture customer-specific midsoles with 3D printing technology to provide each customer tailored comfort and fit. The approach had to be completely rethought to specifically coordinate both the process and the material properties.

Manufacturing silicone soles with the 2-component print head from ViscoTec

The manufacturing solution is realized through a combination of technologies: a manufacturer of 3D printers, a 2-component silicone and the ViscoTec print head. QUANT-U is a 3 step process that begins with the measurement of the customer’s feet with scanners and wearable sensors. Next, the data obtained are evaluated with a sophisticated algorithm and optimized for the respective feet with a simulation. Midsole geometries are optimized for the individual and their activity by adjusting structures, patterns and densities. The resulting 3D printed midsoles are personalized according to the unique orthopedic parameters of the wearer and allow a much more comfortable fit than conventional shoe soles.

3D printing of the 2-component silicone optimally counteracts the high mechanical stresses that occur in everyday life. This is due to the unique silicone properties combined with the algorithmic design of each midsole. It is also possible to produce personalized shoe soles in large quantities and thus serve the masses.

The cooperation with the ViscoTec print heads offers the customer numerous advantages:

- Use of a heat cured 2-component silicone

- Precise 3D printing results thanks to the use of the 2-component print head

- Ensuring uniform mixing of the 2-component silicone in the static mixing tube

The post 3D printed silicone midsoles appeared first on ViscoTec Pumpen- u. Dosiertechnik GmbH.